Premium Flight Gear Bag & Kneeboard

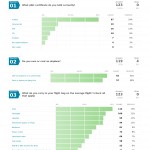

In May of 2014, I met with the owners of Sporty’s Pilot Shop to discuss developing a high-end line of flight gear bags and kneeboards for pilots. We discussed goals, examined existing competitors products and talked about what we needed to learn from our target market, so that we could assemble a survey. Here is some of the information we collected:

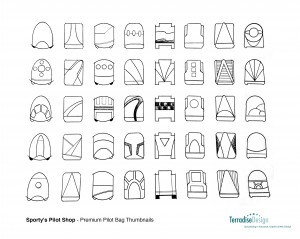

After analyzing key features of competing products, and the survey results, I sat down to sketch some form exploration.

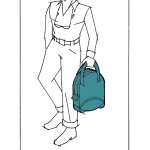

We also explored how these products are most commonly used. A convertible bag solution seemed to fit best. Here we are showing the versatility of a convertible design:

From there, I worked with my business partner, David Schwanemann, to develop some concept sketches to move the project forward. We showed these sketches as part of a presentation to Sporty’s on Tuesday, May 20th, 2014:

After our presentation, we discussed the pros and cons of each concept, and selected concepts 2 and 4 to move ahead with. We decided that a premium bag needed high quality materials during this meeting, so our next round of concepts explored materials as well as the revised form:

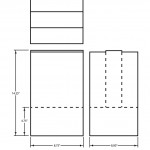

These concepts were reviewed in early June, and concept 2 was selected as the final design with some subtle revisions. Bag proportions were approximately known, but it was now time to nail them down for interior compartment/mapping purposes. This drawing was supplied to Sporty’s after our meeting, so that everyone was clear on the space we have to work with:

From this drawing, compartment mapping were planned and final drawings were developed to be sent to the manufacturer. Here is an overview of these materials:

Handi-Cart 2.0

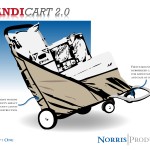

In July of 2008, a contractor working with Sporty’s Pilot Shop asked me to redesign their “Handi-Cart” product, which was a strong seller, but suffered from some significant functional issues that the company was interested in addressing. The budget for the project was tight, so it was decided that as many “off-the-shelf” parts would be used as possible.

Sporty’s Original Handi-Cart

The project began with a customer survey, identifying key areas for product improvement. The results of this survey heavily influenced our design direction, with feedback and suggestions including: increasing wheel size and load capacity, adding a lockable adjustable handle and front casters, adding a locking mechanism for the cart so it would stay open and collapsed when needed and adding a rubberized coating behind the wheels, to keep the canvas from wearing out prematurely. All this needed to be accomplished while maintaining as near the current storage size and weight as possible, and not adding significantly to the cost of the product. The Handi-Cart was manufactured in China, so flat-pack shipping was also something to keep in mind.

With some of this data to work from, I began developing concepts for the redesigned product. Here were some of my initial ideas:

These concepts were reviewed, the best ideas were selected and a revised concept was generated incorporating all elements:

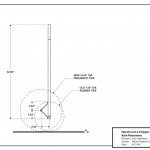

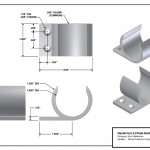

I developed engineering drawings for some of the parts that needed to be manufactured:

The product went into production and was sold by Sporty’s from 2008 until late last year. Here are some photos of the final production unit, from Sporty’s marketing materials: