Human Factors

A course on principles for designing safe, functional, and ergonomically pleasing products. In addition to reading, writing, lecture, discussion, tours and guest speakers, students will complete a group design project, focusing on human factors components of the design process, and present their findings to the class.

Students completing this course:

• Create & develop research by using ethnography, questionnaires, focus groups, contextual interviews, task analysis, immersive design and usability studies.

• Have an understanding of the foundations of anthropometrics and human cognitive processes.

• Have an increased awareness of diverse societal factors influencing product design decision making.

• Apply key principles for designing safe, functional and pleasing products.

• Have a basic understanding of human psychological and physiological infirmities & disorders.

• Demonstrate improved oral, written and multimedia communication skills

This course was co-developed with Professor Pam Ecker and Adjunct Instructor, Howard Baum.

Introduction and History of Human Factors

We begin the class with a discussion on the purpose of human factors in industrial design, focusing on the value of knowing your audience.

Next comes an abbreviated history of designing products for use by humans. We begin by making sure students understand that the concept of designing products for use by humans is not new, discuss the foundations of the formal field of study, discuss Henry Dreyfuss, Niels Diffrient and Alvin R. Tilley’s contributions, and point out modern day resources for human factors data including the HFES organization and CDC website.

Reading & Reference Guides

We currently require two books for the human factors course. Readings are assigned on a weekly basis and class discussions are held. There is a “take home” test associated with the Norman book, where students are required to identify examples of his cognitive design principles around the college.

- “The Measure of Man and Woman”, Henry Dreyfuss Associates

- “The Design of Everyday Things”, by Don Norman

Research Projects

Employing the concept of experiential learning, as much of this course as possible is designed around hands-on data collection and interpretation. A term long design project is introduced during the first week, and we begin exploring methods for learning about the intended audience for the product. During the Spring 2014 Semester, our project was to redesign hand tools for amateur automotive mechanics.

Students were split into two groups. The first group was assigned a Phillips head screwdriver and the second an adjustable wrench.

Throughout the term we reviewed best practices for each of the following research methods, and had the groups set about designing their studies based on these practices.

Ethnography

Students had the option of observing a friend of family member, with an understanding of how this might bias their study. For those without a friend or family member to observe, we made advance arrangements with a group of friendly car enthusiasts who run a Thursday night tech session. They allowed students to come in and collect data on tool usage.

Students recorded their observations, organized and interpreted the results and presented their findings to the class in the form of an IMRD formatted presentation.

Surveys

Building off of what was learned about the target market during the ethnography projects, students composed a list of questions they still needed answers to, and determined how they could reach their target audience to ask these questions. Data is collected, analyzed, and once again reported upon using the IMRD format.

Immersive Design

Once again building off of the completed research, students continue their exploration of the product and its target audience by identifying common usage scenarios where the tools they are studying come up short. They design and build simulations of these scenarios for testing among group members in the laboratory. Once again, students collect data, interpret it, and report on their findings.

Making

Now that students have had the opportunity to explore the problems their users experience with existing tools, they begin proposing potential solutions. Best practices for concept sketching are reviewed, and students present and review multiple sketched iterations until a direction is decided upon. Each student designs their own tools.

- Nick Douglas’ screwdriver concept sketches

- Sarah Hauck (left) and Hannah Mattingly’s screwdriver concept sketches

- Shannon Merten’s adjustable wrench concept sketches

- Mitch Taylor’s adjustable wrench concept sketches

- Chad Morgan’s adjustable wrench concept sketches

Once students have selected a design to move ahead with, they build models of their designs, and present a report of their findings from this exercise.

- Mitch Taylor’s Magnetic Adjustable Wrench Functional Model

- Shannon Merten’s Locking Adjustable Wrench Functional Model

- Sarah Hauck’s Ratcheting Phillips Head Screwdriver Model.

User Trials

Everything done to this point in the term leads to the user trials. These are redeveloped versions of the immersive design exercises, completed with the student designed functional models. A pilot test is performed with fellow faculty and staff members to identify any weaknesses that need to be addressed prior to the full trials.

The test subjects for our user trials during Spring 2014 were automotive technology students from the college.

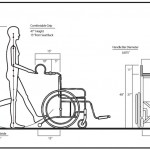

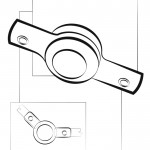

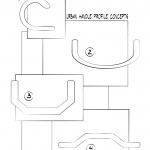

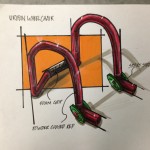

Service Project

Working with the May We Help organization, our human factors students complete a service project for a customer, by applying the lessons learned during the rest of the course. Here are some photos from a project completed for a family in need of a handlebar extension for a pediatric wheelchair.